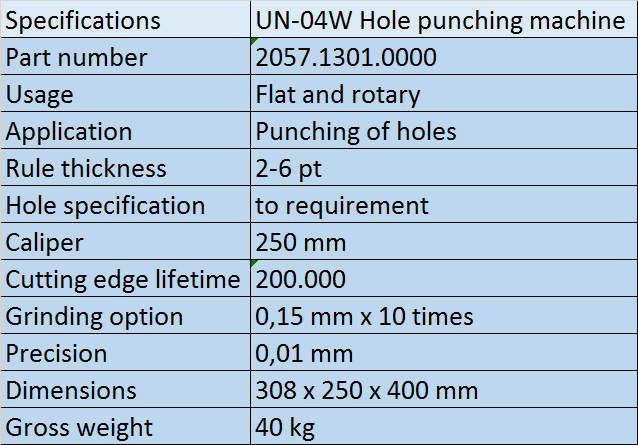

UN-04W Hole punching machine

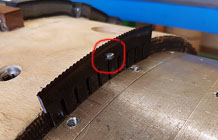

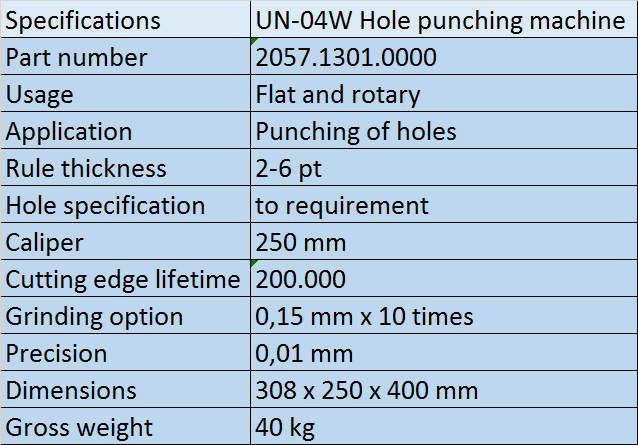

Are you a die maker looking for a Hole Punching Machine? Then you should choose the UN-04W UNIQUE HOLE PUNCHING MACHINE for punching holes in rules from 2 to 6 point thickness. The holes can be made to specification. Thanks to the eccentric system of the machine, punching operation can be performed in an easy and correct way.

UN-04 has been designed for using in the manufacturing of package moulds used in cutting the corrugated board and thick materials.

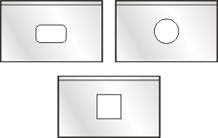

By means of UN-04, you can perform notching at the rules, rill etc. mould materials in height of 8-19 mm and in a width of 3-12 mm and in thickness of 2-6 pt (0,71-2,1 mm).

Thanks to the eccentric system of the machine, notching operation can be performed in an easy and correct way.

Posing with machine is up to 250 mm.

Body of the machine is made of modular sfero casting, and this added strength and durability to the machine. As the machine has a rigid body, it is able to resist the impacts that will occur during the bending operation for many years. The main slide systems within the internal part of the machine have been stoned sensitively and the required heat treatments have been applied with the purpose of minimizing the corrosion.

COATED WITH TITANIUM:

Cutting edges is made of powder metal product imported steels and are passed through the most suitable heat treatment for the cutting operation. In order to increase the resistance of the cutting edges against corrosion and cutting, all our knives are covered with TiN (Titanium). TiN covering provides a 50-70 percent increase in the number of cutting and as it is protected against side corrosions, it increases the life of the rule 4-5 times.

Male knives can be used as two sided. Sharpening option of the knives is 0,15 mm x 10 times.

Hole Punching Machine UN-04W