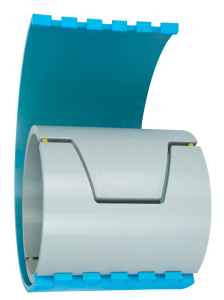

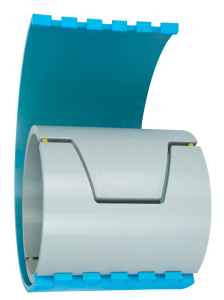

G4 Snap-Sleeve™ bearing System

The Dicar G4 Snap-Sleeve™ system is a die cut bearing upgrade.

Improve your diecutting quality and make cover rotation a lot faster and easier.

The Dicar Snap-Sleeve™ principle is used in the innovative Die Cut Bearing Upgrade and brings a new level of ease-of-use and efficiency to your die cutting station. With the new patented Snap-Sleeve™ you can remove just 1 section of the individual bearing sections and move all other sections over to the other side. This makes installation and mounting a lot easier. The “split bearing” design accommodates thermal expansion to maintain consistent cover mounting. The short change-over time allows your operators to change over in between jobs and assure a consistent surface at all time. Rotating your covers is a must to achieve a regular cover surface at all time. Our Bearing systems allows you to do so in seconds.

Dicar Snap-on Emba bearing upgrade close-up

FEATURES:

- New patented “Snap Sleeve” bearing design

- Uses standard covers with a hidden finger system like the Dicar A2R covers

- Allows removal of individual bearing segments for efficiency and ease of use

- Ideal for ‘Side Set’ machines

- Split bearing design accommodates thermal expansion for consistent and easy mounting

- Bearings slide along cylinder for easy rotation

- Operator can install covers from one location and slide them into place

- Also ideal as a retrofit on Emba’s with a bearing system!

ask for a quotation on your machine at: sales@dicar.eu

Dicar Snap-on system installation on Emba 170 from Dicar BV on Vimeo.